Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

H3 features a good hand feel and is designed to be used where high bond strength is required.

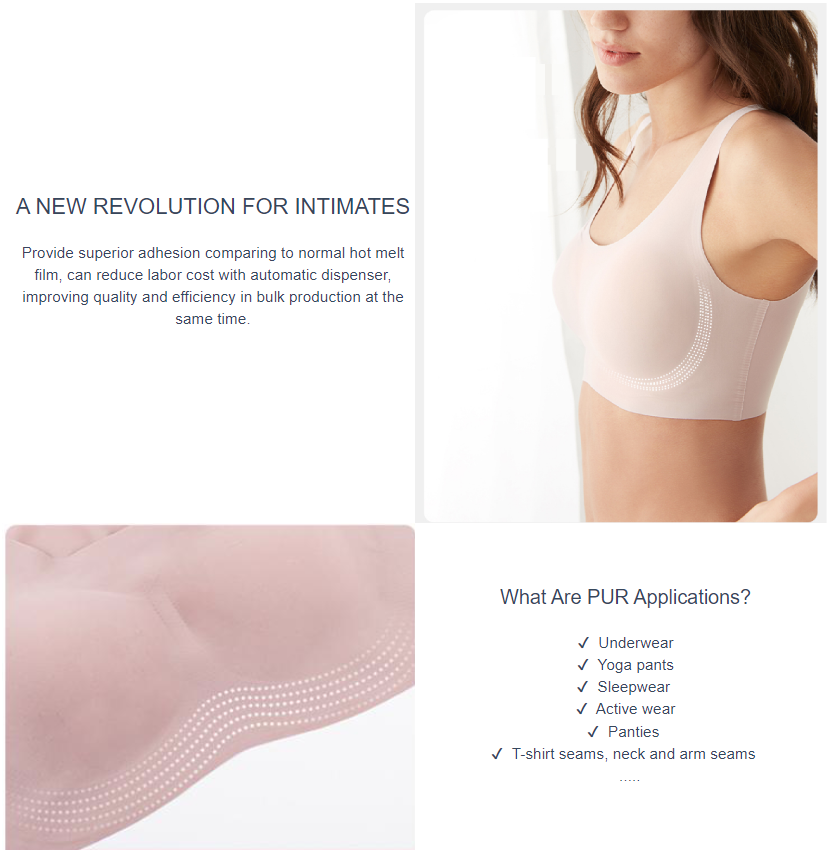

H-Series pur glue provides much high bonding adhesion than normal hot melt film, can reduce labor cost with automatic dispenser, improving quality and efficiency in bulk production at the same time. H3 features a good hand feel and is designed to be used where high bond strength is required.

| Article | Surface drying time | Hand feel | Operation Condition | RecommendedBonding Conditions | Curing Time(Hours) | Intervals between dotting & heat press(mins) |

|---|---|---|---|---|---|---|

| H3 | Fast(20-30s) | Very Soft | Softening Point: 110 - 130℃Spraying Temperature: 200 - 230℃ | Machine Setting: 55 - 95 °CDwell Time: 8 - 12 secondsPressure: 1 – 1.2 Bar | ≥24h | ≤ 20 mins |

Ordinary thermoplastic polyurethane hot melt adhesives are not resistant to high temperatures and can be dissolved after curing, so their applications are limited. To overcome the shortcomings of ordinary hot melt adhesives, reactive polyurethane hot melt adhesives (also known as moisture-curing hot melt adhesives) have been developed.

Some features of Fast surface drying time glue

1. Solvent-free, one liquid type. Unlike solvent-based adhesives, which require a drying process, there is no problem of environmental pollution and poisoning due to solvents. The bonding process is simple, and sizing methods such as roller coating or spraying can be used, and it is suitable for various automatic assembly lines.

2. It can be glued at low temperatures. The melting temperature of polyurethane reactive hot-melt adhesive is lower than that of general hot-melt adhesive (170~200°C), and it can be applied at low temperatures and can be used at 100-120°C. It saves energy consumption, reduces the corrosion of the gluing device, and is suitable for bonding heat-sensitive materials (such as plastics, etc.).

3. Good operability. The two adherents can be fixed in a short time, so the assembly can be quickly transferred to the next processing procedure to improve work efficiency.

4. Long exposure time. In recent years, researchers from various countries have devoted themselves to prolonging the research of reactive hot-melt adhesives and exposure time (adjustable from 5s to 60min), to facilitate the assembly of large-area and complex-shaped components.

5. Long pot life: the pot life can reach 16h at 150°C and 3 days at 90°C.

6. Excellent heat resistance, cold resistance, water vapor resistance, chemical resistance, and solvent resistance. Compared with the original hot melt adhesive, due to the cross-linked structure of the reactive hot melt adhesive, the listed properties are greatly improved.

7. Low shrinkage. The volume change is small during curing and temperature difference so that the adherend will not be damaged by stress.

8. Without losing the original characteristics of polyurethane. Like polyurethane, the molecular structure of its reactive hot melt adhesive can be designed according to needs, so that the melting temperature, melt viscosity, initial viscosity, exposure and curing time, flame retardancy, and even flexibility, hardness, bonding strength, compression Resilience, etc. can be adjusted freely. It has a strong polarity, high wettability to the surface of the adherend, and a wide range of bonding objects.